We're Hiring

- Asst. Manager / Deputy Manager (Pithampur, Indore-M.P., India)

- Asst. Manager / Deputy Manager / Manager HR (Oragadam, Chennai)

- Technical Assistant / GET / Service Engineer (PAN India)

- GET / Sales Executive (PAN India)

Please send your resume to careers@ricelake.co.in or visit our Careers Page for more information.

What is a Control Desk

and How Does it Work?

It consists of the central control desk, MCC panel, Local Control Station and weighing indicator controllers.

Rice Lake uses a programmable weighing controller (920i) or any PLC with latest input, output, and analog modules (based customer suggestion).

Used for loading of cement, fly ash (or) coal in wagons, a control desk enables operators to simultaneously load up to 8 stations.

Applications

- Single Point Flow Regulation

- Multi-Point Blending

- Silos / Hoppers

- Multi-Point Discharges

- Open Stockpile Reclaim

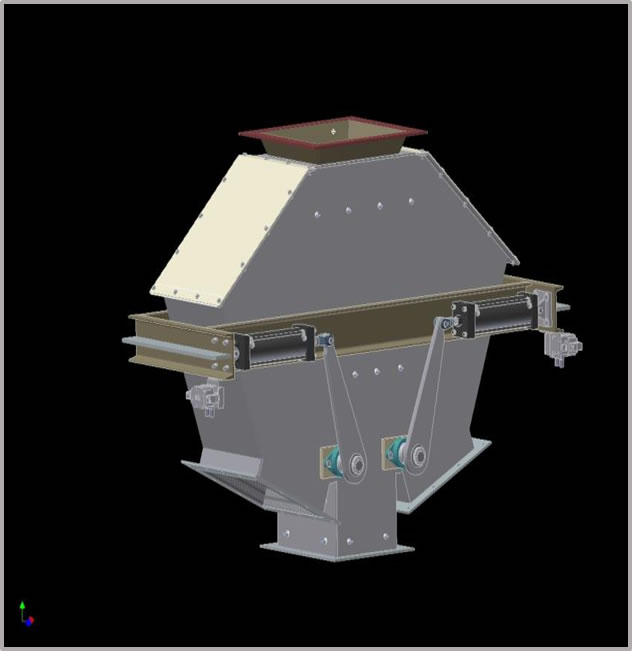

Mass Flow Feeders (DBMFLO)

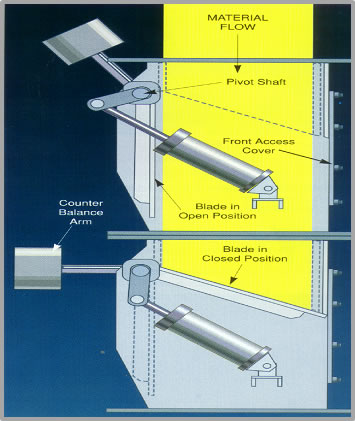

Feeder performs as a volumetric feed rate control device which has the capability of adjusting to varying material flow characteristics.

Features:

- Both blades move allowing the feeder to reach larger flow rates before reaching vertical blade Discharge opening is aligned longitudinally with the centerline belt

- The blades move through a smaller angle for a given opening allowing a lower discharge rate compared to single blade feeder

- Extremely low maintenance requirements and exceptionally long operational life

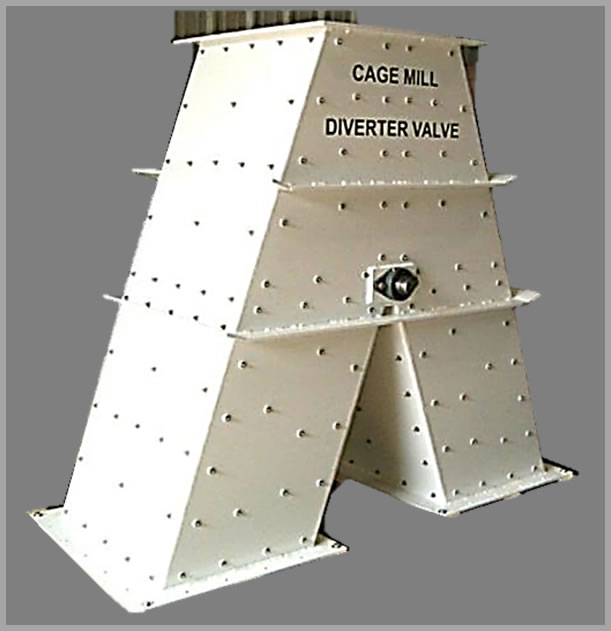

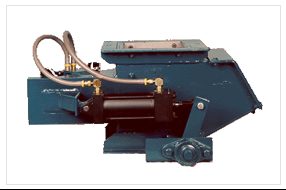

Belt Feeder Gates

This gate is highly applicable where controlled and smooth flow with least impact is desirable. In this gate discharge opening is aligned longitudinally with the center-line of the belt conveyor, which produces and improved material profile on the belt. The belt feeder performs as a volumetric feed rate control device, which can adjust varying material flow properties. The belt feeder gate has few moving parts, consumes minimum energy

This gate is highly applicable where controlled and smooth flow with least impact is desirable. In this gate discharge opening is aligned longitudinally with the center-line of the belt conveyor, which produces and improved material profile on the belt. The belt feeder performs as a volumetric feed rate control device, which can adjust varying material flow properties. The belt feeder gate has few moving parts, consumes minimum energy

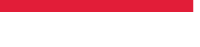

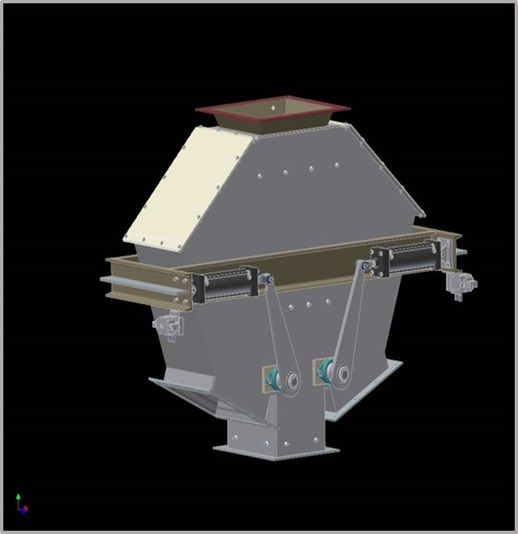

Diverter Gate

There are variety of Diverter gates for Diverter the flow of material from one direction to another. These units are also available in a number of other configurations, including Trimester and Quadverter combinations

There are variety of Diverter gates for Diverter the flow of material from one direction to another. These units are also available in a number of other configurations, including Trimester and Quadverter combinations

Features:

- Diverts gravity flow when cutting through a standing column is not required

- Heavy-duty components

- Abrasion resistant blade

- Various elastomeric seals

- Various sizes and angles of diversion

- Optimal outboard bearings

- A double blade design is also available

- Can be used for diversion and flow splitting of materials

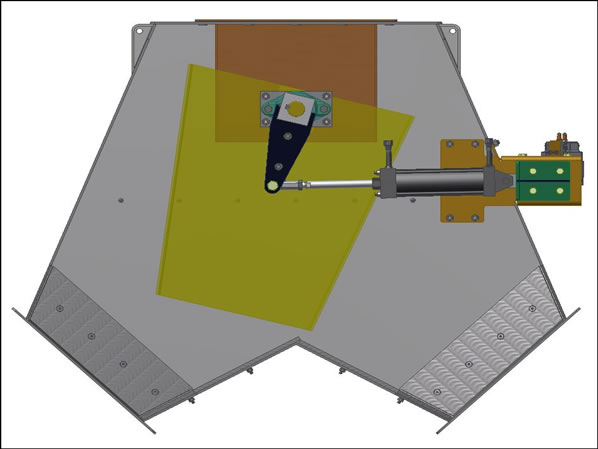

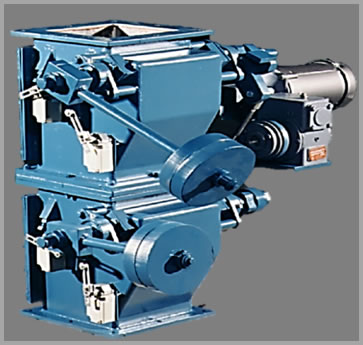

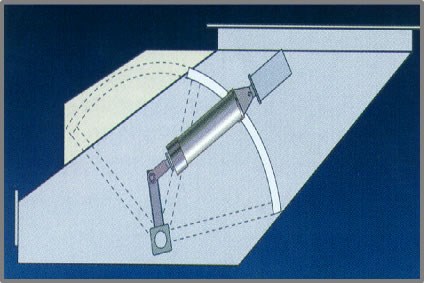

Rolling Blade Belt Feeder

Features

- Introduces flow in the direction that the belt is running.

- Chute incorporated as part of the gate

- This design is unique in that is provides both precise material flow regulation and positive shutof

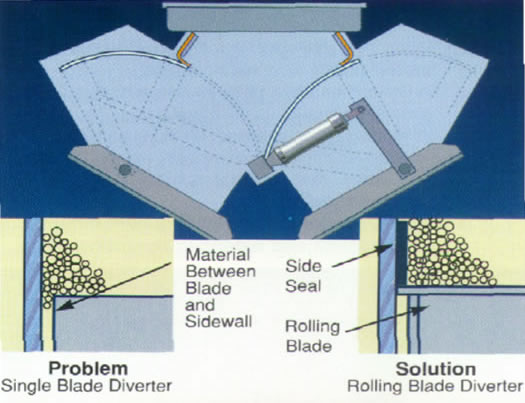

Rolling Blade Gates

These gates meter or control material flow. They are best suited for partially open positions.

These gates meter or control material flow. They are best suited for partially open positions.

The repeatability of flow at intermediate rates is said to be good. These units can be used as Diverter gates in the Diverter, Trimester, and Quadverter configurations.

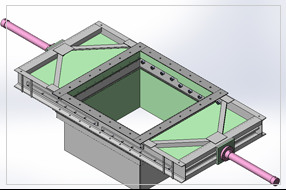

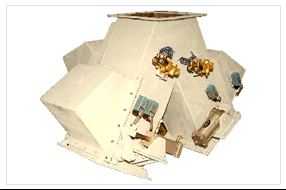

Clam Shell Gates

The single or duplex clamshell gate is an old standard for cutting off material flow when loading hoppers, bins and other containers.

The single or duplex clamshell gate is an old standard for cutting off material flow when loading hoppers, bins and other containers.

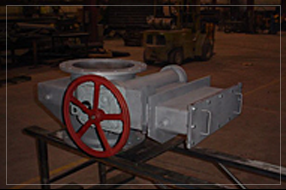

Double Blade Slide Gates

A rolling slide gate is a heavy-duty gate with a lot of operational advantages. Limit switches, activators and position indicators can be combined to interface with your control logic. Unique seal arrangement that optimizes both sealing and cleaning of the blade.

A rolling slide gate is a heavy-duty gate with a lot of operational advantages. Limit switches, activators and position indicators can be combined to interface with your control logic. Unique seal arrangement that optimizes both sealing and cleaning of the blade.

Coal Valve Gates

The term coal valves comes from specific use in the utility industry. The unit is heavy –duty slide gate with self cleaning internals and an exceptionally long life. The design features lend themselves to coal fired utility plant applications.