We're Hiring

- Asst. Manager / Deputy Manager (Pithampur, Indore-M.P., India)

- Asst. Manager / Deputy Manager / Manager HR (Oragadam, Chennai)

- Technical Assistant / GET / Service Engineer (PAN India)

- GET / Sales Executive (PAN India)

Please send your resume to careers@ricelake.co.in or visit our Careers Page for more information.

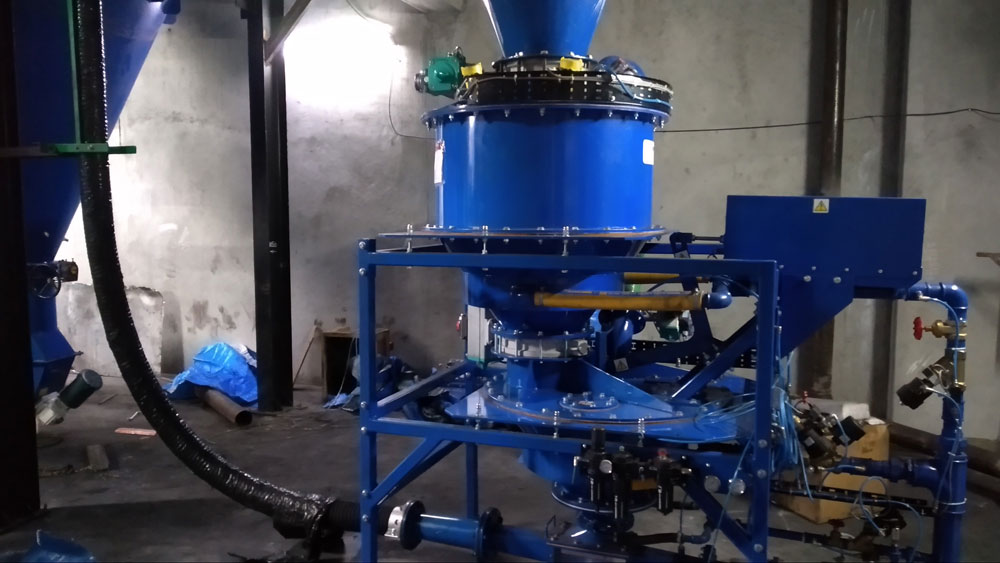

Carbon Batching

These systems are highly beneficial as these ensures consistency of operation, increased output and eliminating wastages and are used for dispensing a precise amount of carbon l into the Intermix/Banbury. Carbon batching system which consists of weigh hoppers with pneumatically operated butterfly valves and vibrators for batching of carbon.

Carbon batching system is installed in almost all the tire & technical rubber industries.

- Carbon fully auto pneumatic conveying

- Easy to use , maintain for long years

- Positive pressure , Vacuum system available

- In house manufacturing of storage silos ( 1 T – 10 T ), day silos, feeding devices , electrical panels

- Best in class HMI programmable weight controller 920 I, 1280 I

- In house software ,PLC/ Scada screen development

- Indicator lamps and push button for operator acknowledgement

- Accurate and effective batching.

- Expansion of carbon for future line possible

Chemical Batching

- J type Bin Capacity( 30 Kg )

- Full quantity of bag can be emptied into storage bin

- Intake is automated with validation to avoid wrong materials with expiry date

- Bin mouth opening is bigger & easy for intake and weighing operations

- Motorized trolley ensures smooth movement and less operator fatigue

- Operator and weighing details given in a computer monitor screen

- Bar code will get printed once all batches are completed as per sequence

- Operator friendly, integrated application software for easy access of weighment screen

- Indicator lamps and push button for operator acknowledgement

- Accurate to +/- 1 Gram and effective batching.

- Expansion of chemical bin system ( in future ) feasible

- FIFO system for intake ( optional )

- Used to weighing powder & granular type material

- Finds application in all tyre, chemical, technical rubber industries.

Oil Scales

It is ideally suited for liquid weighing and accurate batching preparation of liquids involving various batch components and formulations. The oil weighing system with inbuilt weighing scale and discharge valve with Weighing range of 1-120kg and the dynamic accuracy of +/-25gms.

- Latest , robust design

- Custom capacity available to suit your need

- Electrical trace heating (optional ) available

- Sturdy load cell used

- Special pump usedto pump oil at hi pressure in to mixer

- Operator friendly, Easy to operate

- Indicator lamps and push button available

- Accurate and effective batching.

- Expansion of Liquid / oils for future possible

- Material of Construction : Mild Steel / Stainless Steel ( optional )

Polymer Weighing

Polymer weighing scale is designed to with stand the tough environment of the mixing room. Polymer weigher is capable of unprecedented weighing accuracies of +/- 1gms.

- Latest, robust design

- Light and Heavy duty model available

- Custom length, width , height & capacity available to suit your need

- Sensors kept at scale for inter locking

- Special , Sturdy load cell are used to deflect impact of drop

- Operator friendly,simple . easy steps to maintain

- Best in class weight indicator

- Accurate and effective weighing .

- Material of Construction : Mild Steel